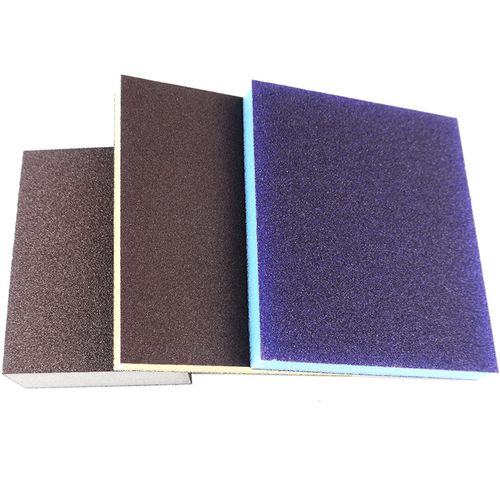

Why can black sic P sand/powder be used to make sponge sandpaper/blocks?

Normally, black silicon carbide F sand/powder is used for bonded abrasives, while black sic P sand/powder is often used in the manufacture of coated abrasives.

Why is black silicon carbide P sand/powder used when producing sponge sandpaper/sand blocks?

The reasons for using black sic P sand/powder in the production of sponge sand blocks mainly include its excellent physical and chemical properties.

Black silicon carbide P sand has the following characteristics:

High hardness and wear resistance: The hardness of black silicon carbide is second only to diamond and corundum. It has high microhardness and can maintain sharpness during long-term grinding. It is suitable for occasions that require high wear resistance.

Excellent thermal conductivity: Black silicon carbide can quickly dissipate the heat generated during grinding, avoid overheating of the workpiece, and improve processing quality and efficiency.

Stable chemical properties: Black silicon carbide is not easily affected by chemicals such as acids and alkalis, and can maintain stable performance in a variety of harsh environments.

Good self-sharpening: Black silicon carbide can continuously produce new cutting edges during the grinding process to maintain a good cutting effect.

These characteristics give black sic P sand/powder the following advantages in the production of sponge sand blocks:

Improve grinding efficiency: Due to the high hardness and good grinding performance of black silicon carbide, the grinding wheel using black silicon carbide has higher grinding efficiency.

Improve processing quality: Black silicon carbide grinding wheels can produce finer wear marks and improve the finish and roughness of the workpiece surface.

Extend service life: The high wear resistance of black silicon carbide makes the grinding wheel have a longer service life, reducing the number and cost of replacing the grinding wheel. Therefore, black sic P sand has become an ideal choice for the production of sponge sand blocks due to its excellent physical and chemical properties.

Physical and chemcial data:

|

chemcial data |

||||||

|

size |

SIC |

F.C |

Fe2O3 |

H2O |

||

|

P240# |

≥98.5% |

≤0.2% |

≤0.2% |

≤1% |

||

|

physical data |

||||||

|

Bulk density |

Volume density |

microhardness |

Mohs Hardness |

|||

|

1.4-1.7g/cm3 |

3.2-3.5 g/cm3 |

2840-3320kg/mm2 |

9.15 |

|||