Can black silicon carbide be used for making sic ceramic seal ring?

yes, of course.

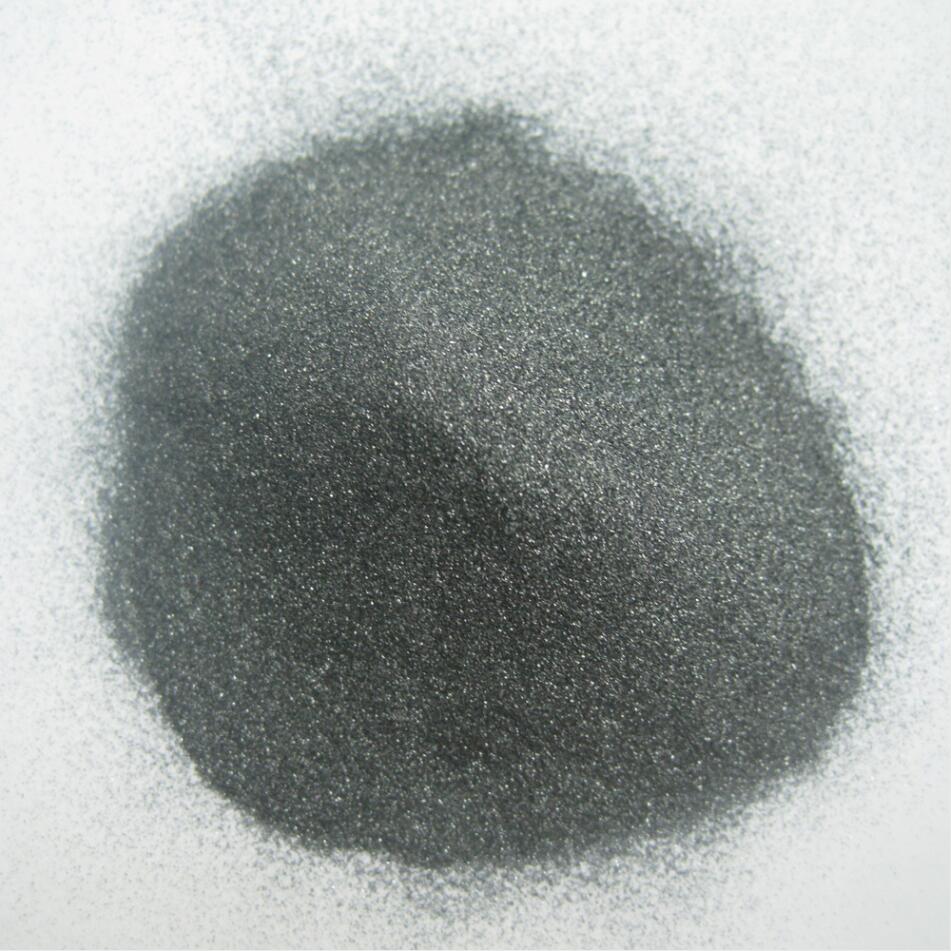

Our black silicon carbide has high purity and good quality. The ceramic sealing ring produced is durable and efficient, and is loved by customers. Our customer use black sic F120# to make sic ceramic seal ring.

![]()

Description:

It is produced by smelting quartz sand, petroleum coke (or coal coke), wood chips, and other raw materials in a resistance furnace. It appears as a black opaque body with hexagonal crystals and a Mohs hardness of 9.15. Second only to diamond and boron carbide, it possesses brittle and sharp properties with a certain degree of conductivity.

Typical Physical Properties:

| Mohs Hardness | 9.15 |

| Melting Point | 2250℃ |

| Maximum Use Temperature | 1900℃ |

| True Density | 3.2-3.4g/cm3 |

| Knoop Hardness | 2840-3320kg/mm2 |

Grit Size & Chemical Analysis:

| Grits Size | F 8# 10# 12# 14# 16# 20# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220#mesh | |

| Chemical Composition (%) | SIC | ≥98.5 |

| F.C | ≤0.2 | |

| Fe2O3 | ≤0.2 | |

| H2O3 | ≤1 | |