The core advantages of green silicon carbide in cemented carbide sandblasting绿碳化硅在硬质合金喷砂中的核心优势:

| 优势维度Advantage Dimension | 具体说明 |

|---|---|

| 极高的硬度Extremely high hardness | 莫氏硬度达9.5,仅次于金刚石,足以有效切削硬质合金。

Its Mohs hardness reaches 9.5, second only to diamond, and is sufficient for effectively cutting hard alloys. |

| 优异的自锐性Excellent self-renewal ability | 磨粒在工作中会微破碎,持续露出新的锋利刃口,保持高效的切削能力。

During operation, the abrasive particles will undergo minor fragmentation, continuously exposing new sharp edges, thus maintaining their efficient cutting ability. |

| 良好的导热性Good thermal conductivity | 能快速传导喷砂产生的热量,减少工件(尤其是硬质合金刀片等)因局部过热导致性能下降的风险。

It can quickly conduct the heat generated by sandblasting, reducing the risk of performance degradation of the workpiece (especially hard alloy blades and the like) due to local overheating. |

| 粒度均匀,表面质量高Uniform particle size and high surface quality | 颗粒均匀,喷砂后表面粗糙度一致,为后续涂层提供良好附着力。

The particles are uniform, and the surface roughness after sandblasting is consistent, providing excellent adhesion for the subsequent coating. |

| 化学性质稳定Chemically stable | 抗腐蚀,喷砂后残留物少,不影响后续工艺。

Corrosion-resistant. The residue left after sandblasting is minimal and does not interfere with subsequent processes. |

根据你的喷砂目的来确定粒度:

Determine the grit size of green silicon carbide based on your sandblasting objective:

For rapid removal of scale, burrs, and old coatings (coarse cleaning): Choose coarse grit such as F24, F30, or F36.

For achieving a uniform surface and improving coating adhesion (roughening): Choose medium grit such as F46, F60, or F80.

For obtaining a smooth, matte surface (finishing): Choose fine grit such as F100, F120, or F150.

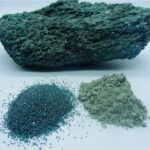

Green silicon carbide F220#:

![]()