What is the effect of adding green silicon carbide powder to semiconductor mortar cutting materials?

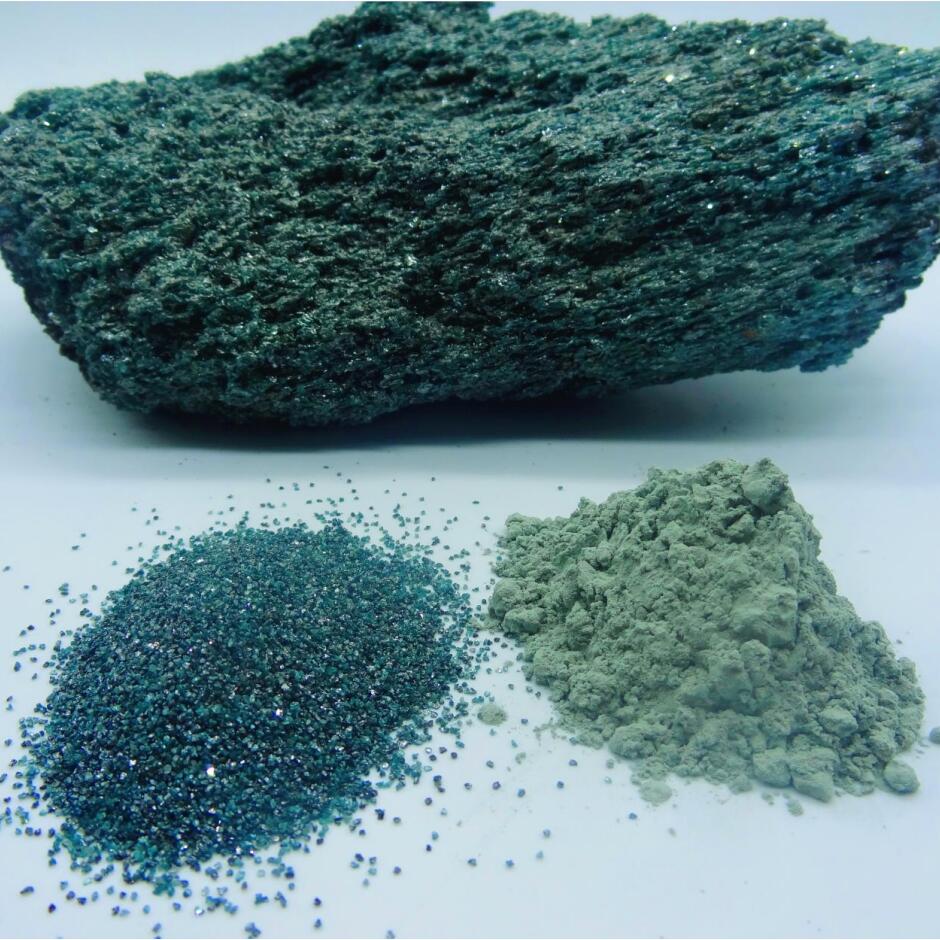

Green silicon carbide powder is used in semiconductor dicing primarily due to its physical properties and process advantages:

Hardness and Wear Resistance

With a hardness of up to 9.5 on the Mohs scale, close to diamond (Mohs scale 10), green silicon carbide micropowder effectively cuts semiconductor materials such as silicon wafers and silicon carbide wafers. Its high wear resistance ensures blades or wire saws maintain their sharpness longer during dicing, reducing the need for replacement.

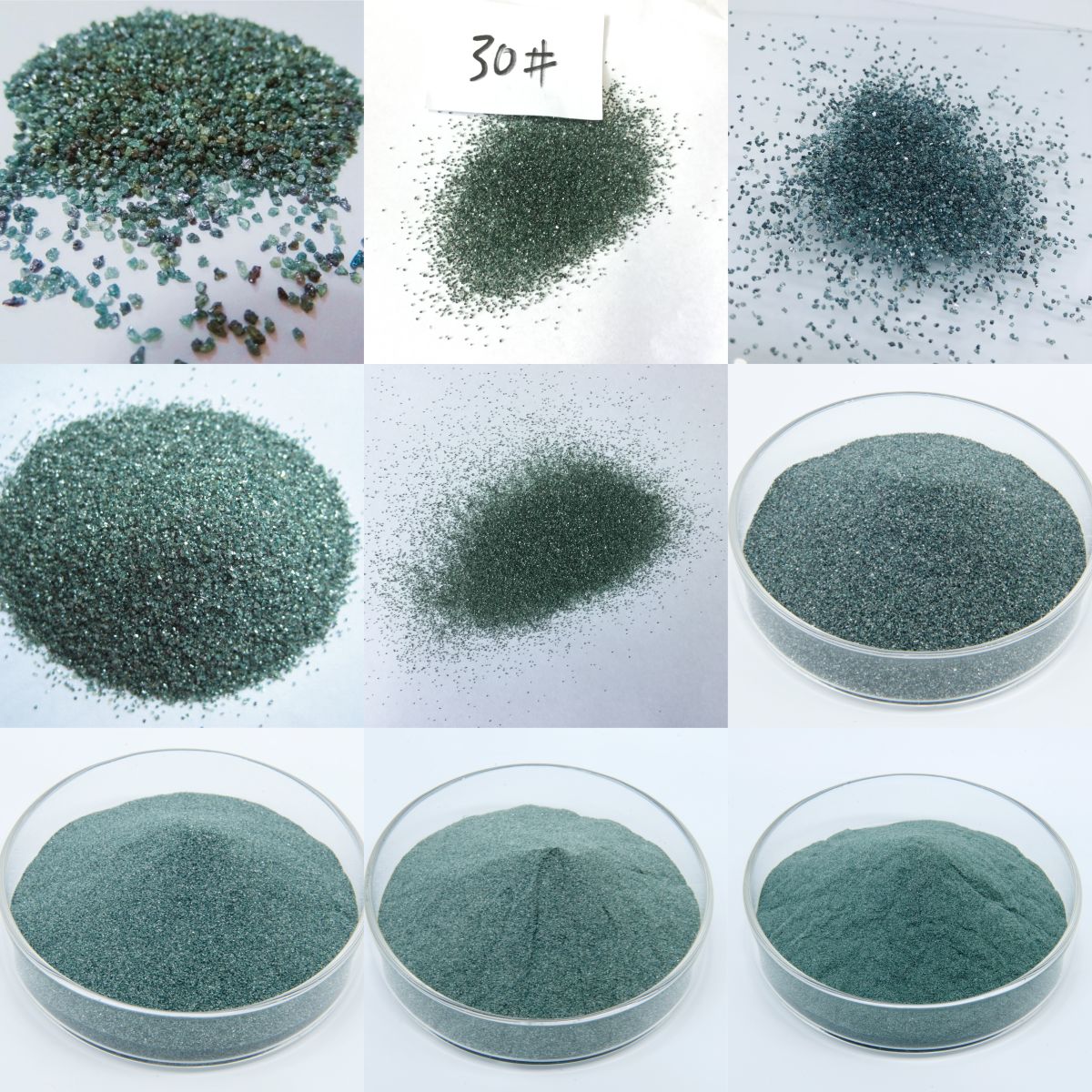

Cutting Efficiency and Quality

Green silicon carbide micropowder cutting blades utilize diamond-coated blades or diamond wires, separating materials through high-speed rotation or unidirectional circular motion. Compared to traditional methods, green silicon carbide cutting improves cutting efficiency while ensuring a straight, scorched, and warped cut surface with a surface finish of 2-3 microns.

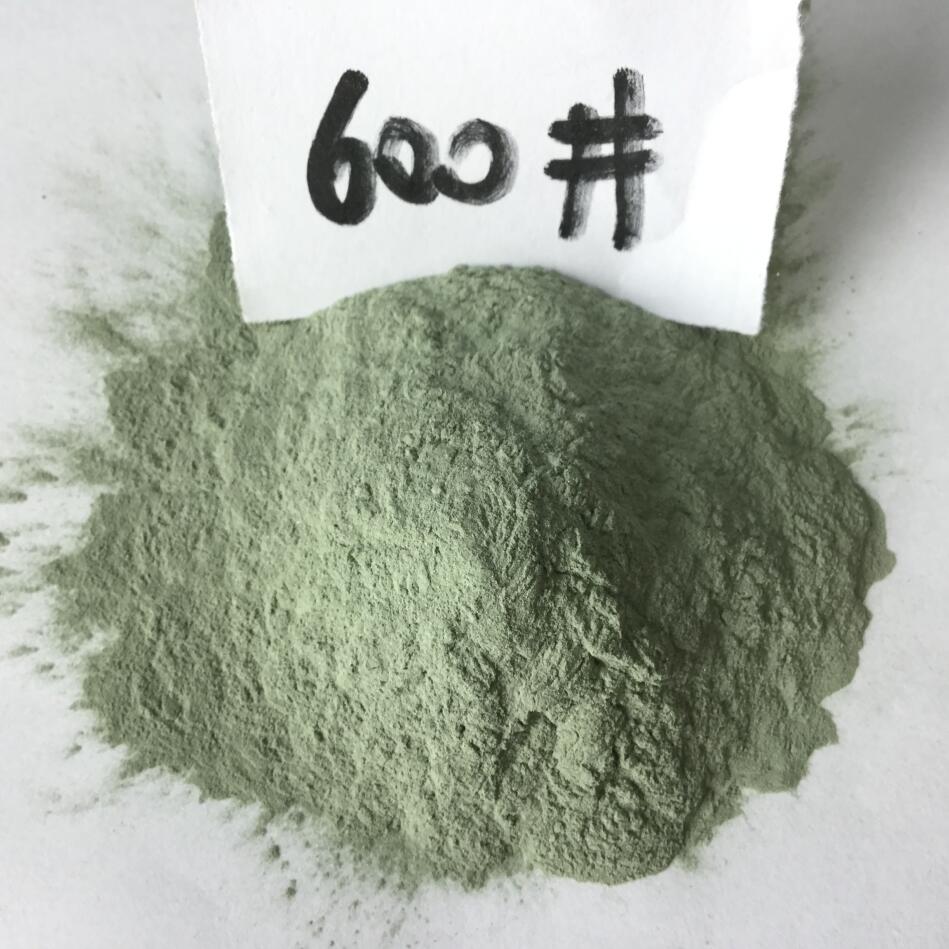

Application Compatibility

In semiconductor manufacturing, green silicon carbide is commonly used in critical processes such as wafer grinding and dicing. It removes microscopic surface bumps and damaged layers, providing a high-quality substrate for subsequent processes such as photolithography and ion implantation. Its low damage properties can reduce chemical and mechanical damage and improve product yield.