Why use green sic 280# sandblasting optical glass?

The median particle size of green sic 280#, as detected by the laser method, is generally 60-65 um. We can also provide customers with particle sizes that meet their special requirements.

Green sic 280# can be used for sandblasting optical glass. Its characteristics are as follows:

Applicability:

Green silicon carbide has a Mohs hardness of 9.4 and offers strong cutting performance, making it suitable for precision polishing of hard and brittle materials such as optical glass. Its uniform particle size distribution and high thermal conductivity reduce temperature rise during polishing, minimizing thermal damage.

Polishing Results:

Green silicon carbide breaks down its surface passivation layer during polishing, exposing a fresh cutting edge and maintaining continuous polishing performance. Its uniform particle size distribution prevents localized overloading and under-processing, ensuring surface accuracy.

Process Advantages:

High-Temperature Stability: With a melting point of 2700°C and a low coefficient of thermal expansion, it remains stable at high temperatures.

Corrosion Resistance: Resists chemical corrosion from acids, alkalis, salts, and other chemicals, making it suitable for complex processing environments.

Environmental Performance:

Non-toxic and non-polluting, it meets environmental requirements.

It is recommended to use a wool wheel or other tools when polishing to improve efficiency and reduce surface damage.

Description:

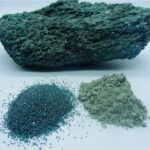

Green sic is a green translucent hexagonal non-metallic mineral product made from petroleum coke and high-quality silica as the main raw materials, with salt as an additive, and is produced through 2200° high-temperature smelting in a resistance furnace. Then we will get green silicon carbide ingot. After crushing, screening, moisture acid washing, at last we will get different sizes of green sic powder.

| Chemcial data | ||||

| SIC | SiO2 | Fe2O3 | F. Fe | C |

| 99%min | ≤0.2 | ≤0.2 | 0.04% | 0.1% |

| Physical data | ||||

| colour | Mohs hardness | Knoop harnedd | Specific Gravity | Melting Point |

| green | 9 | 2600 | 3.2 g/cm3 | 2600° |

Green sic 280#:

![]()