Green silicon carbide sic for steelmaking

Green silicon carbide’s primary benefits in steelmaking are as follows:

Increasing molten steel temperature

The addition of green sic can raise the molten steel temperature by an average of 48.4°C, with a temperature increase range of 40.3-70.3°C.

Optimizing deoxidation

As a composite deoxidizer, green sic combines with free oxygen in the molten steel to form a low-melting-point slag that rises, increasing deoxidation efficiency by 40%.

Reducing energy consumption

Using green sic for deoxidation in the steelmaking process can reduce electricity consumption by 5%-8% while also increasing the recovery rate of alloying elements such as manganese and chromium (for example, manganese recovery increases from 82% to 90%).

Reducing slag volume

Compared to traditional ferrosilicon deoxidation, green sic reduces dust emissions by 30% and slag volume by 15%, contributing to environmental protection.

Improving molten steel fluidity

The addition of green sic improves molten steel fluidity, facilitating casting and molding. It also reduces the TFe content by 1.3%, minimizing damage to refractory bricks.

Description:

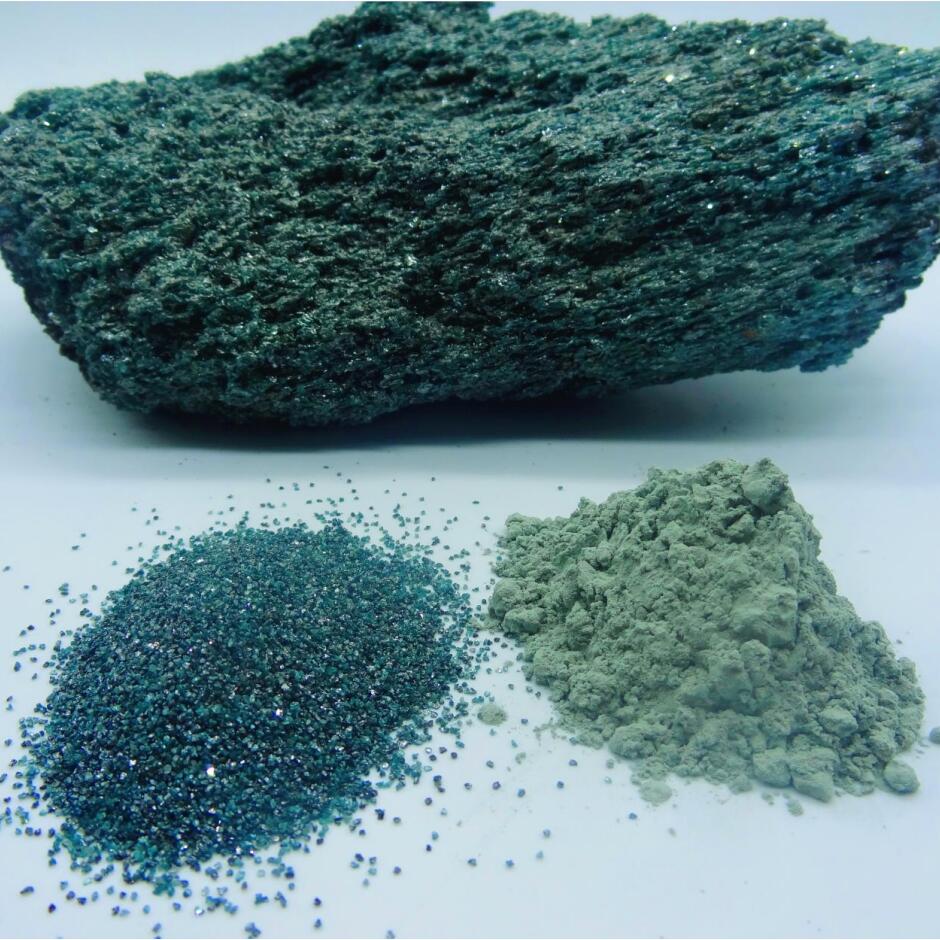

Green silicon carbide is a green translucent hexagonal non-metallic mineral product made from petroleum coke and high-quality silica as the main raw materials, with salt as an additive, and is produced through 2200° high-temperature smelting in a resistance furnace. Then we will get green silicon carbide ingot. After crushing, screening, moisture acid washing, at last we will get different sizes of green sic powder.

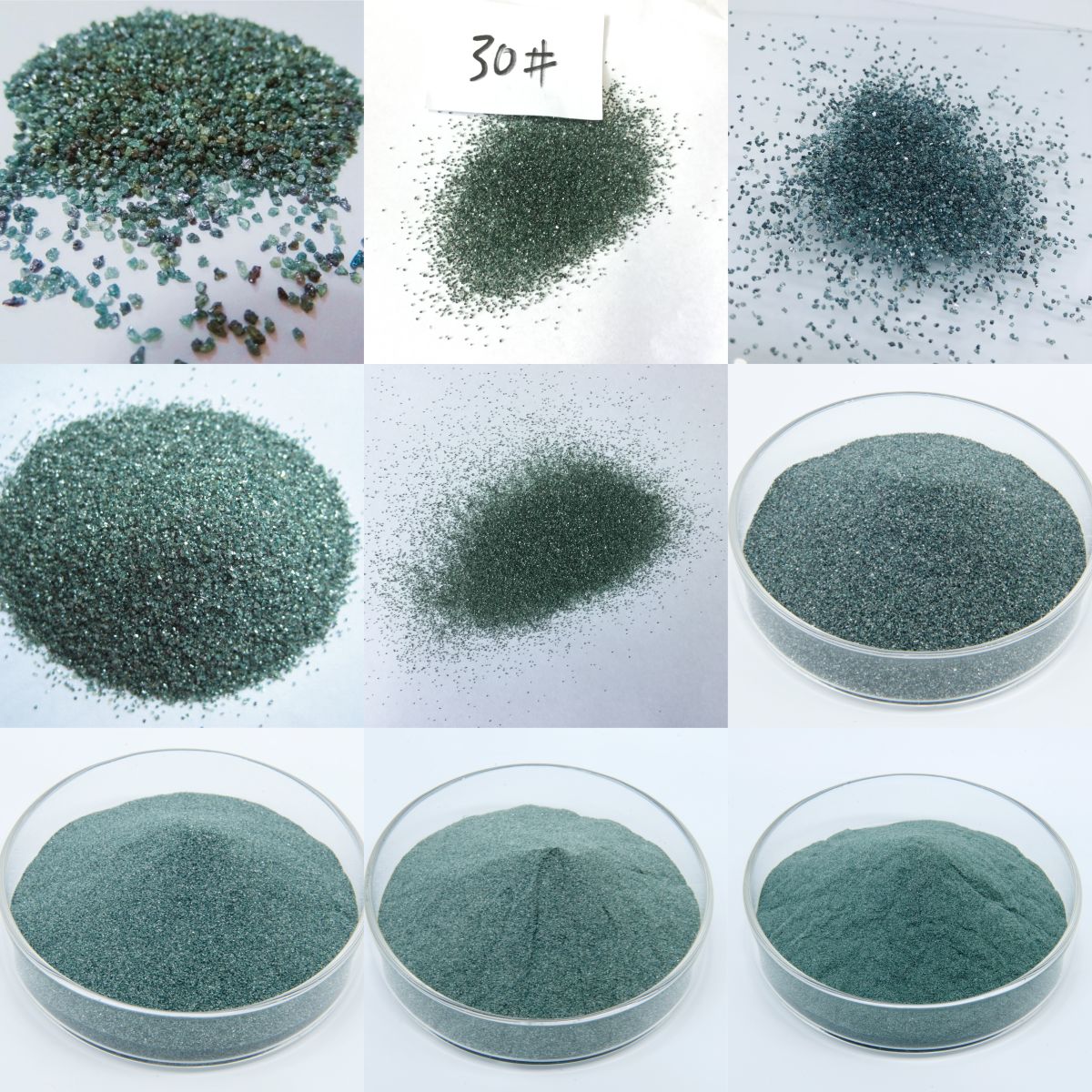

Availabe size:

Section Sand:0-1mm, 1-3mm, 3-5mm, 5-8mm

F-macrogrit-Sizes-bonded F12F14F16F20F22F24F30F36F40F46F54F60F70F80F90F100F120F150F180F220#mesh

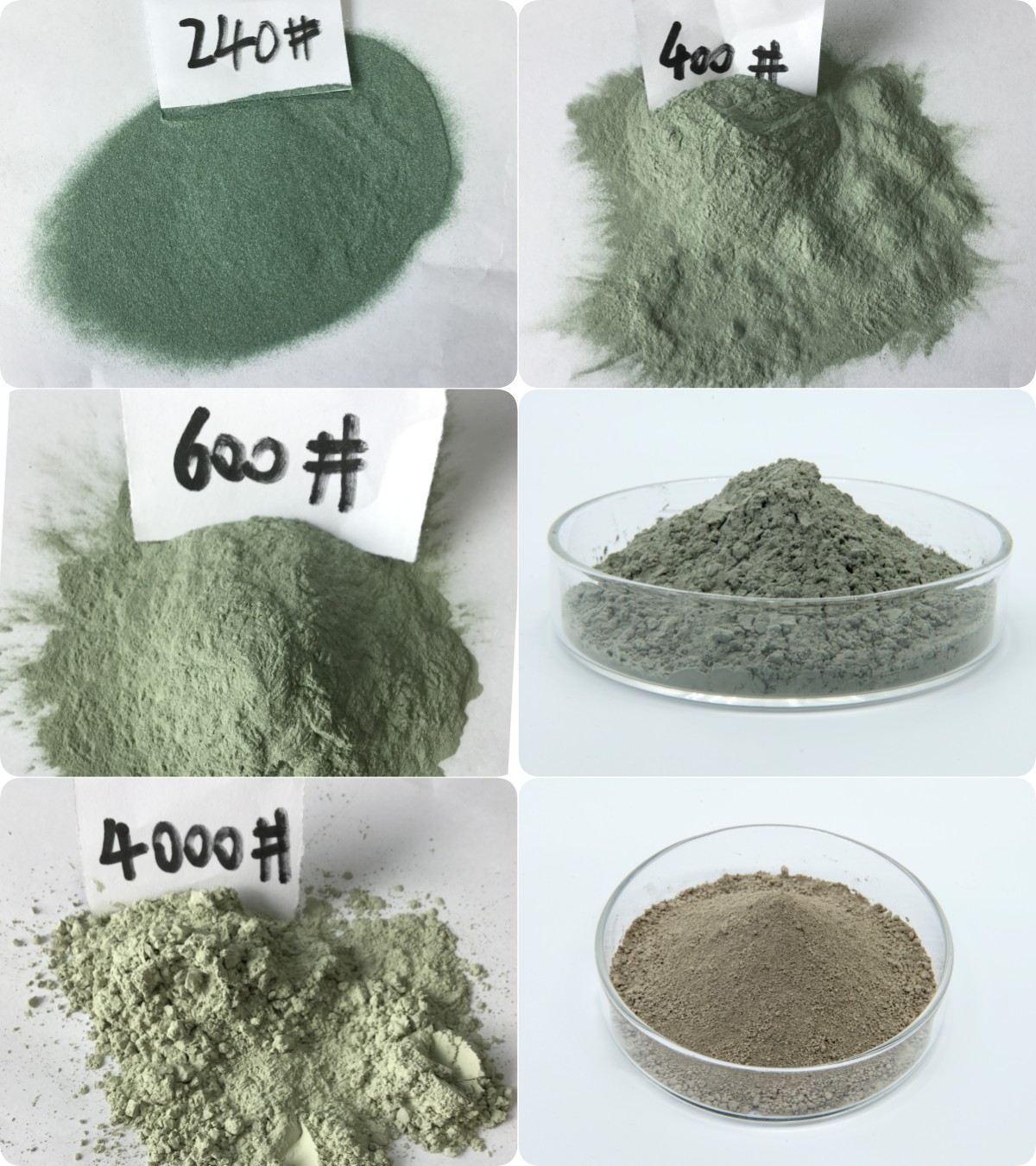

JIS-microgrit-Sizes-bonded 240#280#320#360#400#500#600#800#1000#1200#1500#2000#3000#4000#6000# 8000#10000#mesh

Data for chemcial and physical:

| Chemcial data | ||||

| SIC | SiO2 | Fe2O3 | F. Fe | C |

| 99%min | ≤0.2 | ≤0.2 | 0.04% | 0.1% |

| Physical data | ||||

| colour | Mohs hardness | Knoop harnedd | Specific Gravity | Melting Point |

| green | 9 | 2600 | 3.2 g/cm3 | 2600° |

Green silicon carbide sand:

Micropowder:

Package for green silicon carbide:

- 25KG small bags

- Small bags + pallet

We’re a 26 years green sic manufacturer, our factory was founded in 1999.