Green sic micropowder for semiconductor cutting mortar

What fountion does green sic powder play in semiconductor cutting mortar?

Green sic micropowder is used in semiconductor dicing primarily due to its physical properties and process advantages:

Hardness and Wear Resistance

With a hardness of up to 9.5 on the Mohs scale, close to diamond (Mohs scale 10), green sic powder effectively cuts semiconductor materials such as silicon wafers and silicon carbide wafers. Its high wear resistance ensures blades or wire saws maintain their sharpness longer during dicing, reducing the need for replacement.

Cutting Efficiency and Quality

Green sic powder cutting blades utilize diamond-coated blades or diamond wires, separating materials through high-speed rotation or unidirectional circular motion. Compared to traditional methods, green silicon carbide cutting improves cutting efficiency while ensuring a straight, scorched, and warped cut surface with a surface finish of 2-3 microns.

Application Compatibility

In semiconductor manufacturing, green silicon carbide is commonly used in critical processes such as wafer grinding and dicing. It removes microscopic surface bumps and damaged layers, providing a high-quality substrate for subsequent processes such as photolithography and ion implantation. Its low damage properties can reduce chemical and mechanical damage and improve product yield.

Description:

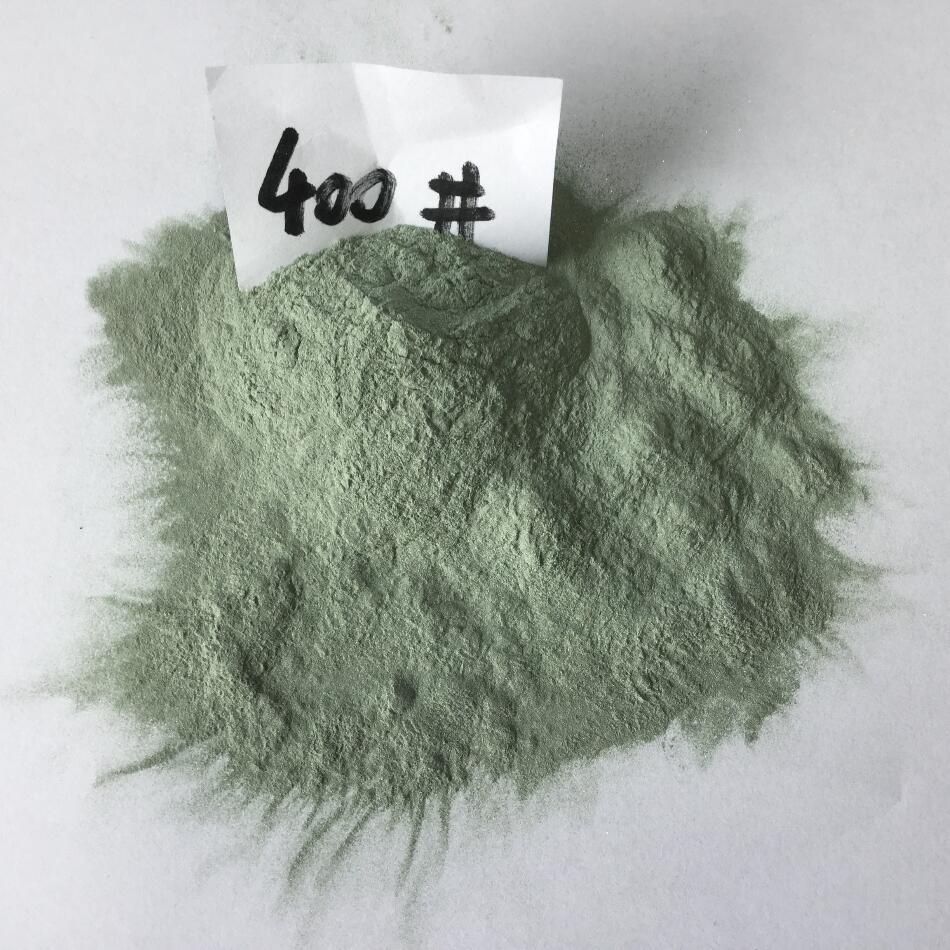

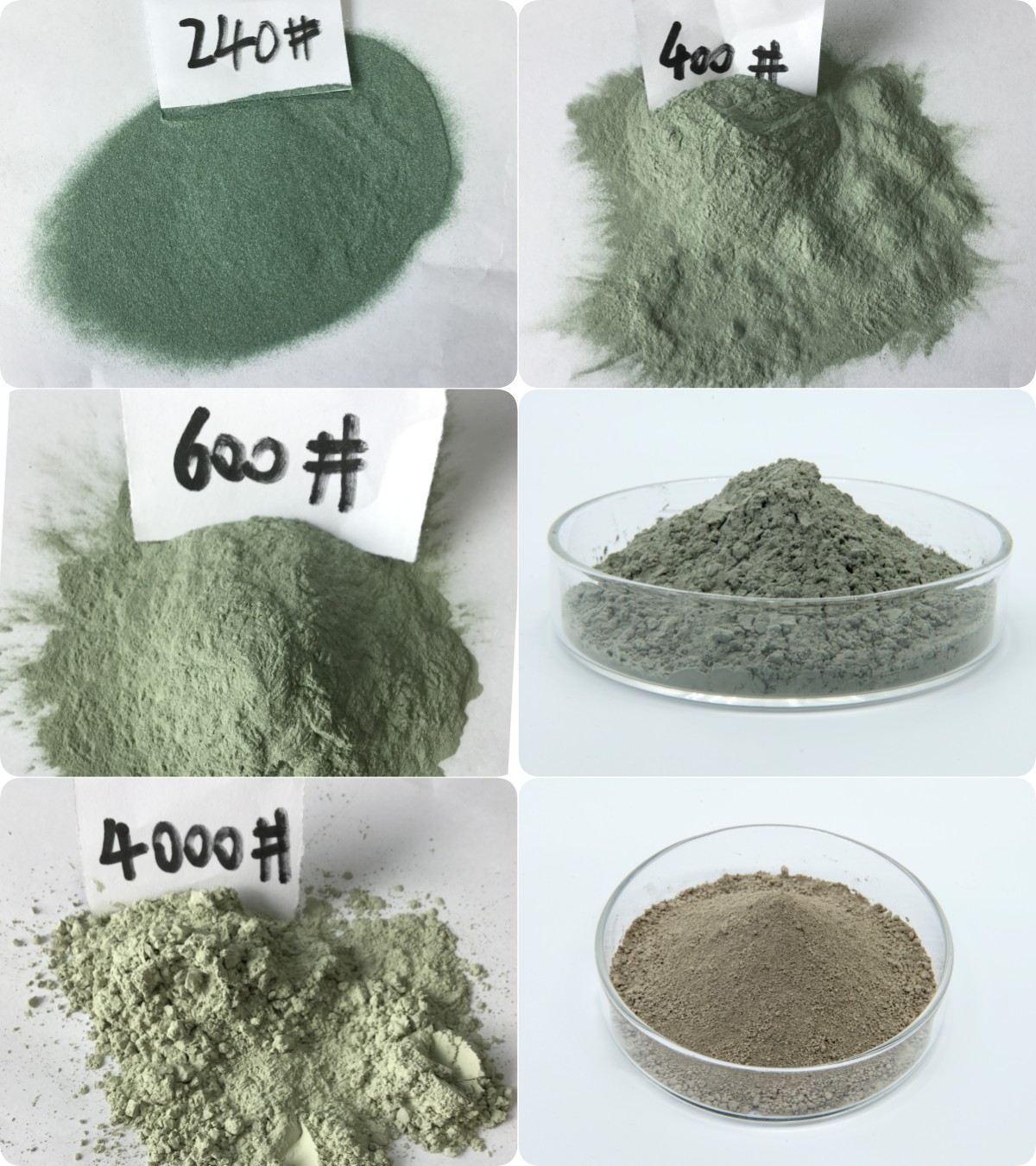

Green sic micropowder is a green translucent hexagonal non-metallic mineral product made from petroleum coke and high-quality silica as the main raw materials, with salt as an additive, and is produced through 2200° high-temperature smelting in a resistance furnace. Then we will get green silicon carbide ingot. After crushing, screening, moisture acid washing, at last we will get different sizes of green sic powder.

Availabe size:

Section Sand:0-1mm, 1-3mm, 3-5mm, 5-8mm

F-macrogrit-Sizes-bonded F12F14F16F20F22F24F30F36F40F46F54F60F70F80F90F100F120F150F180F220#mesh

JIS-microgrit-Sizes-bonded 240#280#320#360#400#500#600#800#1000#1200#1500#2000#3000#4000#6000# 8000#10000#mesh

Data for Green sic micropowder:

| Chemcial data | ||||

| SIC | SiO2 | Fe2O3 | F. Fe | C |

| 99%min | ≤0.2 | ≤0.2 | 0.04% | 0.1% |

| Physical data | ||||

| colour | Mohs hardness | Knoop harnedd | Specific Gravity | Melting Point |

| green | 9 | 2600 | 3.2 g/cm3 | 2600° |

Green sic micropowder:

Packaging for green sic:

- 25KG small bags

- Small bags + pallet