Green/black silicon carbide 320# for polishing disc

The main reason for using green/black silicon carbide in polishing discs lies in its physical and chemical properties, which make it perform well in the polishing process.

Firstly, sic has high hardness and wear resistance.

Secondly, it has good thermal conductivity.

Additionally, the particle size distribution of sic is uniform and it has self-sharpening properties.

Finally, sic has excellent chemical resistance.

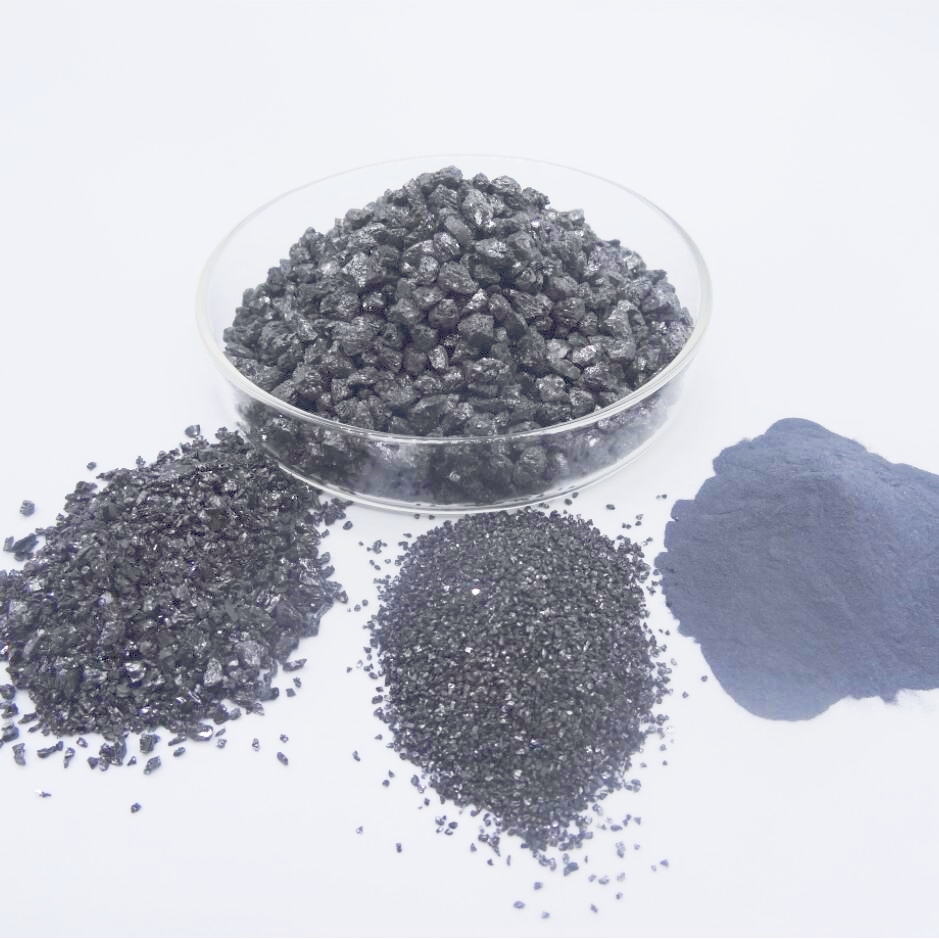

Black silicon carbide:

Black sic is produced by smelting quartz sand, petroleum coke (or coal coke), wood chips, and other raw materials in a resistance furnace. It appears as a black opaque body with hexagonal crystals and a Mohs hardness of 9.15. Second only to diamond and boron carbide, it possesses brittle and sharp properties with a certain degree of conductivity.

Typical Physical Properties

| Mohs Hardness | 9.15 |

| Melting Point | 2250℃ |

| Maximum Use Temperature | 1900℃ |

| True Density | 3.2-3.4g/cm3 |

| Knoop Hardness | 2840-3320kg/mm2 |

Grit Size & Chemical Analysis

| Grits Size | F 8# 10# 12# 14# 16# 20# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220#mesh | |

| Chemical Composition (%) | SIC | ≥98.5 |

| F.C | ≤0.2 | |

| Fe2O3 | ≤0.2 | |

| H2O3 | ≤1 | |

Micropowder Size & Chemical Analysis

| Micropowder Size | W Standard | W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5 W0.5 |

| FEPA Standard | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000# | |

| JIS Standard | JIS240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# | |

| Chemical Composition (%) | SIC | ≥97 |

| F.C | ≤0.3 | |

| Fe2O3 | ≤0.3 | |

| H2O3 | ≤1 |

Black silicon carbide:

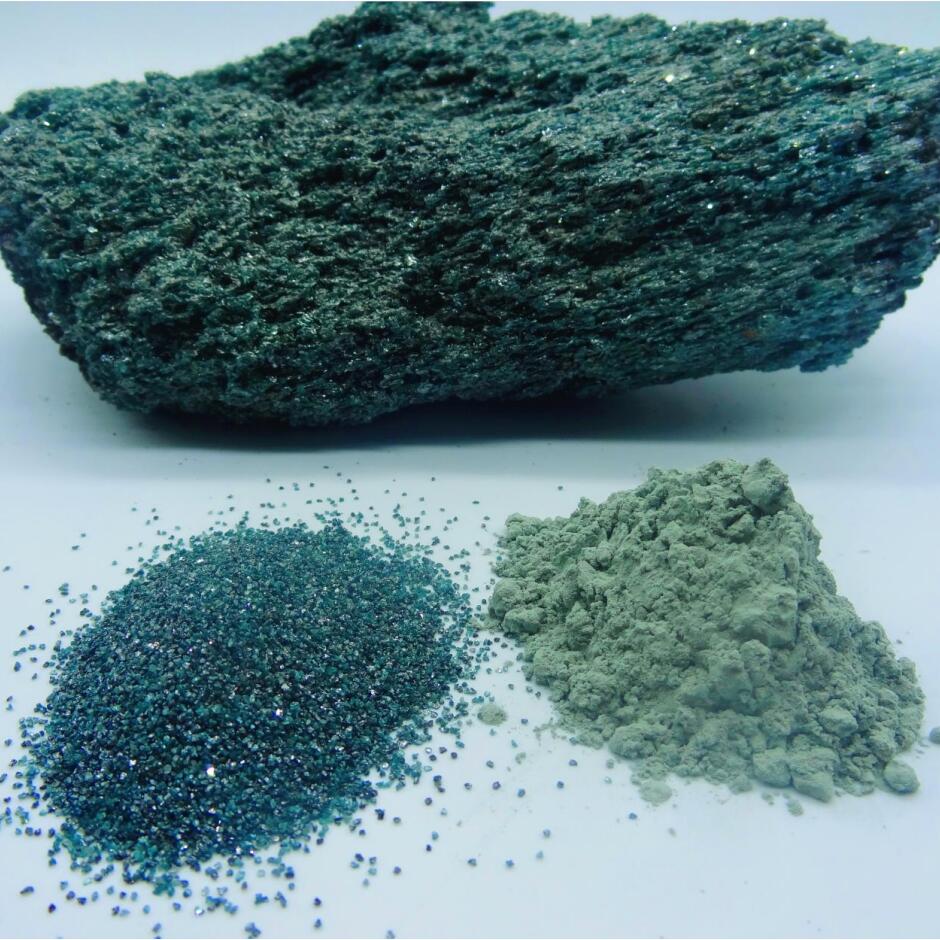

Green sic:

Green silicon carbide is a green translucent hexagonal non-metallic mineral product made from petroleum coke and high-quality silica as the main raw materials, with salt as an additive, and is produced through 2200° high-temperature smelting in a resistance furnace.

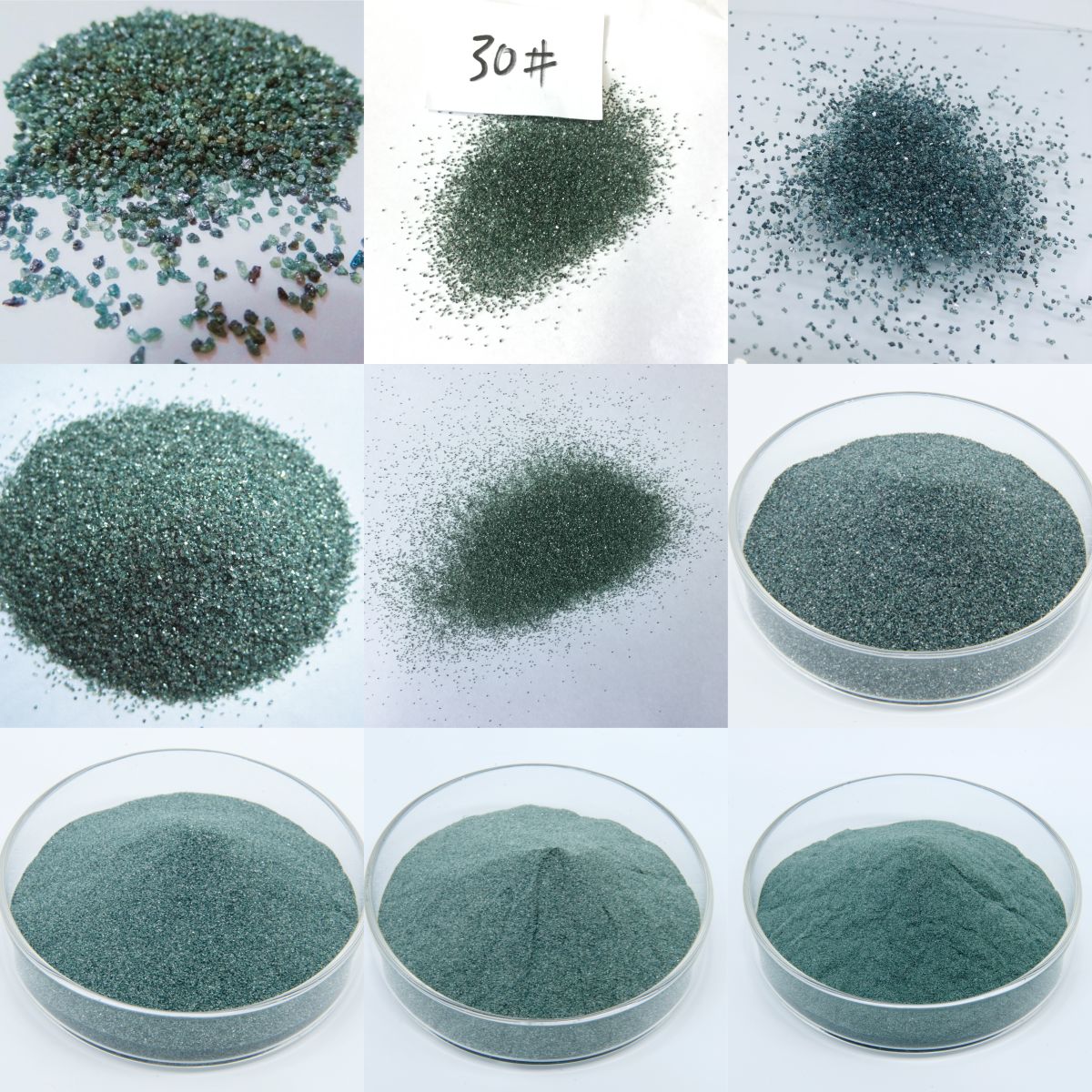

Availabe size for green silicon carbide:

Section Sand:0-1mm, 1-3mm, 3-5mm, 5-8mm

F-macrogrit-Sizes-bonded F12F14F16F20F22F24F30F36F40F46F54F60F70F80F90F100F120F150F180F220

JIS-microgrit-Sizes-bonded 240#280#320#360#400#500#600#800#1000#1200#1500#2000#3000#4000#6000# 8000#10000#

Data for green sic:

| Chemcial data | ||||

| SIC | SiO2 | Fe2O3 | F. Fe | C |

| 99%min | ≤0.2 | ≤0.2 | 0.04% | 0.1% |

| Physical data | ||||

| colour | Mohs hardness | Knoop harnedd | Specific Gravity | Melting Point |

| green | 9 | 2600 | 3.2 g/cm3 | 2600° |

Green silicon carbide:

Packaging for sic:

- 25KG small bags

- Small bags + pallet