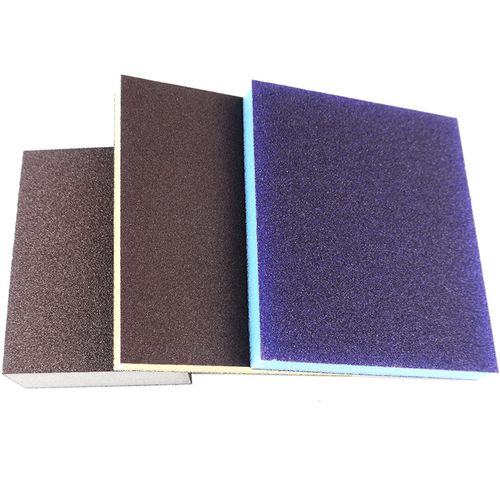

Black SiC P Sand For Sponge Sand Block

Normally, black sic F sand/powder is used for bonded abrasives, while black sic P sand/powder is often used in the manufacture of coated abrasives.

Why is black silicon carbide P sand/powder used when producing sponge sandpaper/sand blocks?

The reasons for using black silicon carbide P sand/powder in the production of sponge sand blocks mainly include its excellent physical and chemical properties.

Black sic P sand has the following characteristics:

High hardness and wear resistance: The hardness of black silicon carbide is second only to diamond and corundum. It has high microhardness and can maintain sharpness during long-term grinding. It is suitable for occasions that require high wear resistance.

Excellent thermal conductivity: Black silicon carbide can quickly dissipate the heat generated during grinding, avoid overheating of the workpiece, and improve processing quality and efficiency.

Stable chemical properties: Black silicon carbide is not easily affected by chemicals such as acids and alkalis, and can maintain stable performance in a variety of harsh environments.

Good self-sharpening: Black silicon carbide can continuously produce new cutting edges during the grinding process to maintain a good cutting effect.

Black sic P sand is made from silica sand and smokeless acetylene. It is made via light resistance from hydrometallurgical, it is black opaque body hexagonal crystal and MOHS -hardness in the 9.15, its hardness just less than diamond and boron carbide, crisp and sharp performance and certain degree of conductive heat. It’s toughness is higher than green silicon carbide, it’s SiC purity 98.5%, it have been used for processing glass,ceramic,stone, refractory materials , ceramic product, cast iron and other metal.

Physical and chemcial data:

|

chemcial data |

||||||

|

size |

SIC |

F.C |

Fe2O3 |

H2O |

||

|

P240# |

≥98.5% |

≤0.2% |

≤0.2% |

≤1% |

||

|

physical data |

||||||

|

Bulk density |

Volume density |

microhardness |

Mohs Hardness |

|||

|

1.4-1.7g/cm3 |

3.2-3.5 g/cm3 |

2840-3320kg/mm2 |

9.15 |

|||

Productive process:

Package for black silicon carbide P sand:

![]()