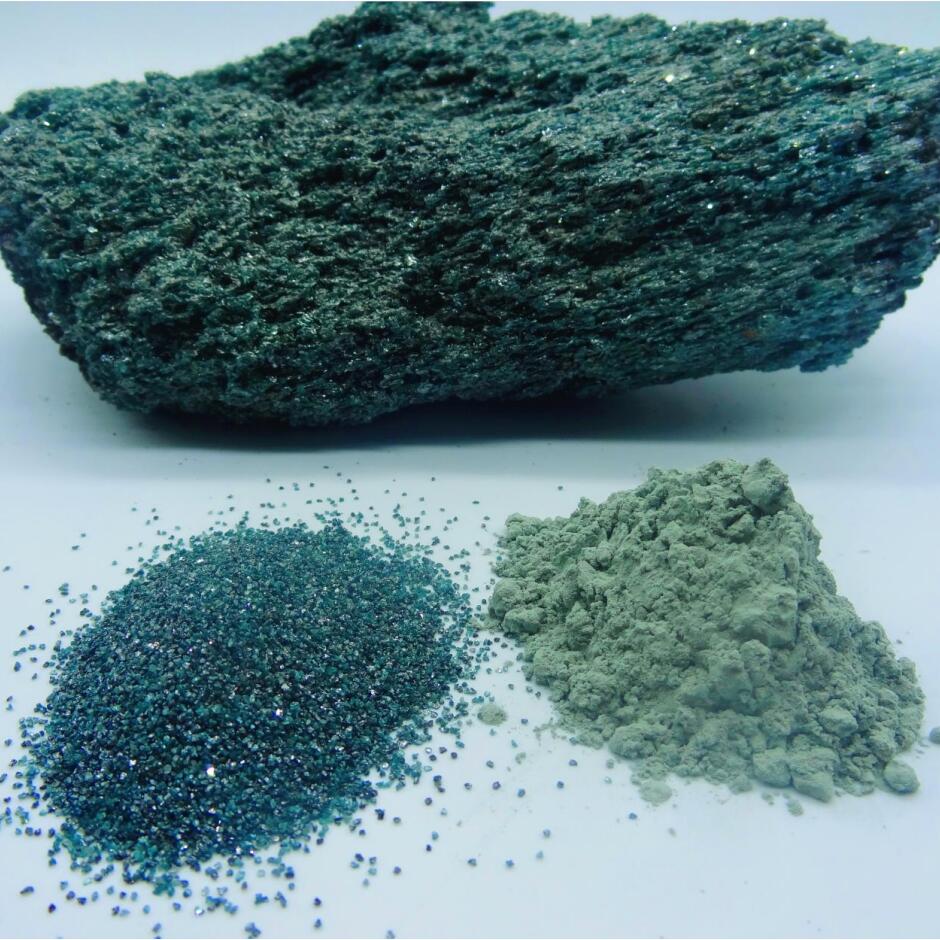

Why use green silicon carbide sand blasting hard alloy?

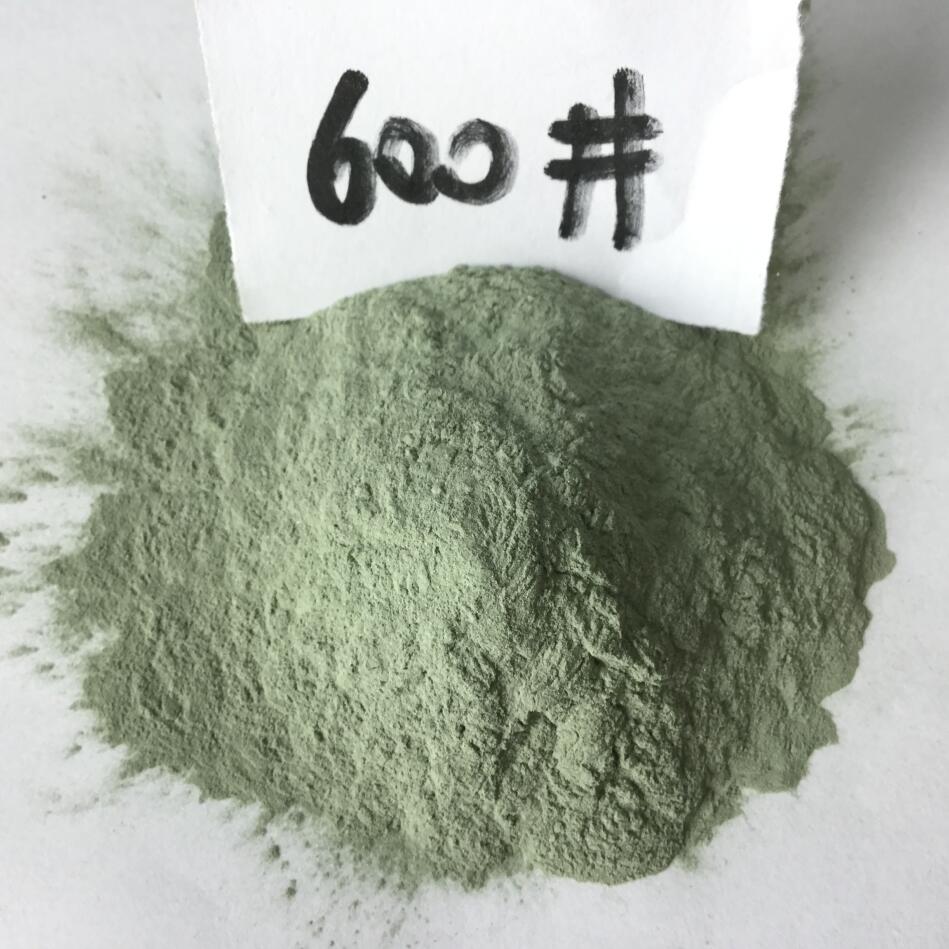

Green silicon carbide has become a common choice for cemented carbide sandblasting due to its comprehensive advantages such as “high hardness that can be easily pierced, good self-sharpening properties and high efficiency, and good thermal conductivity that does not damage the workpiece”.