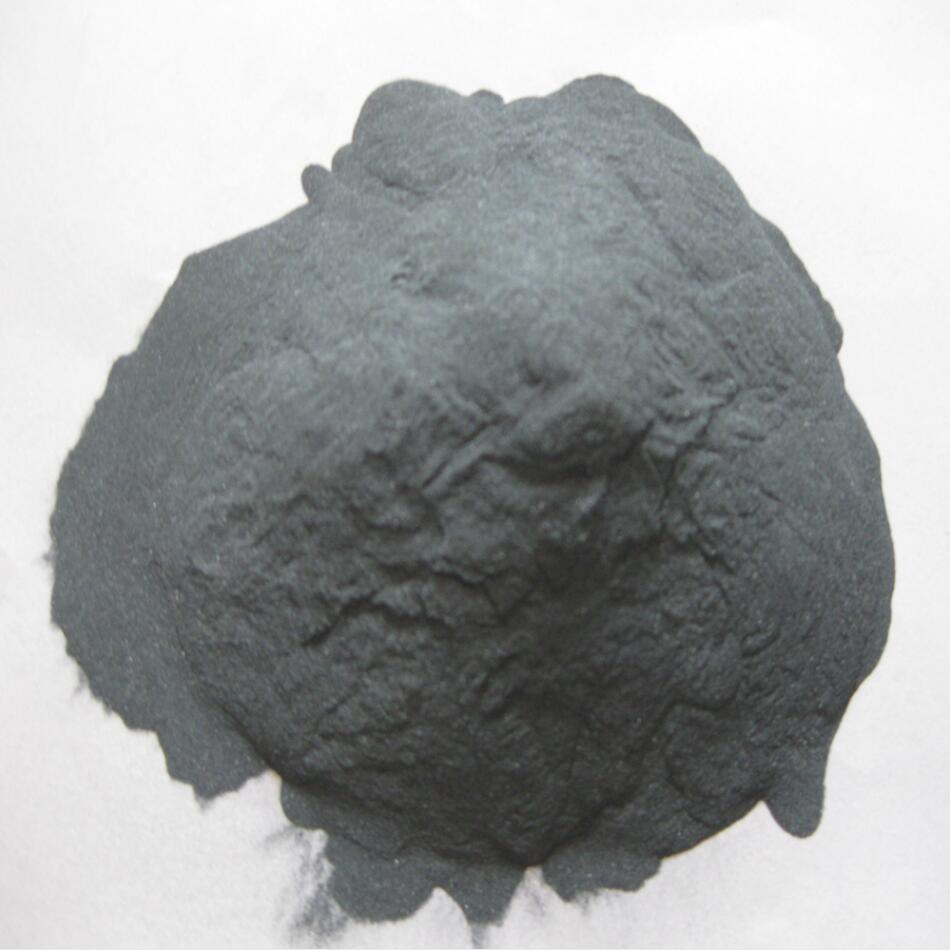

Black SiC Silicon Carbide for abrasives powder

Black SiC Silicon Carbide is quartz sand, petroleum coke in primary raw materials, smelting in the high temperature resistance furnace. Its hardness is between corundum and diamond; the mechanical strength is higher than alumina, brittle and sharp. It has a certain conductivity and thermal conductivity.

(1) As the abrasive: used for abrasive, such as grinding wheels, whetstone, grinding wheel, sand tiles etc.

(2) As the metallurgical deoxidizer and high temperature material.

Four main application areas of SiC: functional ceramics, advanced refractory, abrasives and metallurgical materials.

(3) High purity single crystal, used to manufacture semiconductors, manufacture of silicon carbide fibers.

(4) Silicon carbide is very hard, with excellent thermal conductivity, as a semiconductor and high temperature resistant to oxidation.

The physical and chemical analysis for Black SiC Silicon Carbide:

|

Model: Black SiC Silicon Carbide JIS#600 |

|||

|

Chemical compositions |

Physical properties |

||

|

Items |

Value of specification (%) |

Items |

Property |

|

SIC |

98.55min |

Color |

Black |

|

Melting point |

2600°C |

||

|

F.C |

0.20max

|

Hardness |

9.5 |

|

Bulk density |

≥1.38g/cm3 |

||

|

Fe2O3 |

0.20max |

Real density |

3.20~3.25g/cm3 min |

|

Usage |

1,Grinding wheels 2,Electrical 3,Coated tools 4,Heating elements 5,Polishing 6,Ceramic 7,Lapping 8, Refractory |

||

Usage for Black SiC Silicon Carbide for abrasives powder:

1. The application in the non-ferrous metal smelting industry

Use silicon carbide’s high temperature, strength, good thermal conductivity and impact resistance, for high-temperature indirect heating materials, such as Jian Retort Furnace, distillation furnace trays, aluminum tanks, copper melting furnace linings, zinc furnace arc plate, thermocouple protection tubes.

2. The application in the iron and steel industry

Use silicon carbide’s corrosion-resistance, thermal shock resistance to abrasion and good thermal conductivity for increasing service life of large-scale blast furnace lining.

3. The application in the metallurgical ore processing

Silicon carbide with strong wear resistance, second only to the diamond hardness, is the ideal material for wear-resistant pipe, impeller, pump chamber, cyclone and ore bucket lined, also for the aviation runway. The wear resistance is 5-20 times of cast iron, rubber life.

4. The application in the building materials ceramic and grinding wheel industry

Use its characters of thermal conductivity, heat radiation and high temperature strength to make sheet kiln. It can not only reduce the kiln capacity, but also improve furnace installed capacity and product quality and shorten the production cycle. It is also the ideal indirect materials of sintering ceramic glazed baked.

5. The application in energy saving

Use its good thermal conductivity and thermal stability to make heat exchanger, saving 20% fuel consumption and 35% fuel and improving the productivity by 20-30%. In particular, mine processing plant with a discharge pipeline in place, the abrasion resistant material is 6-7 times more than common.